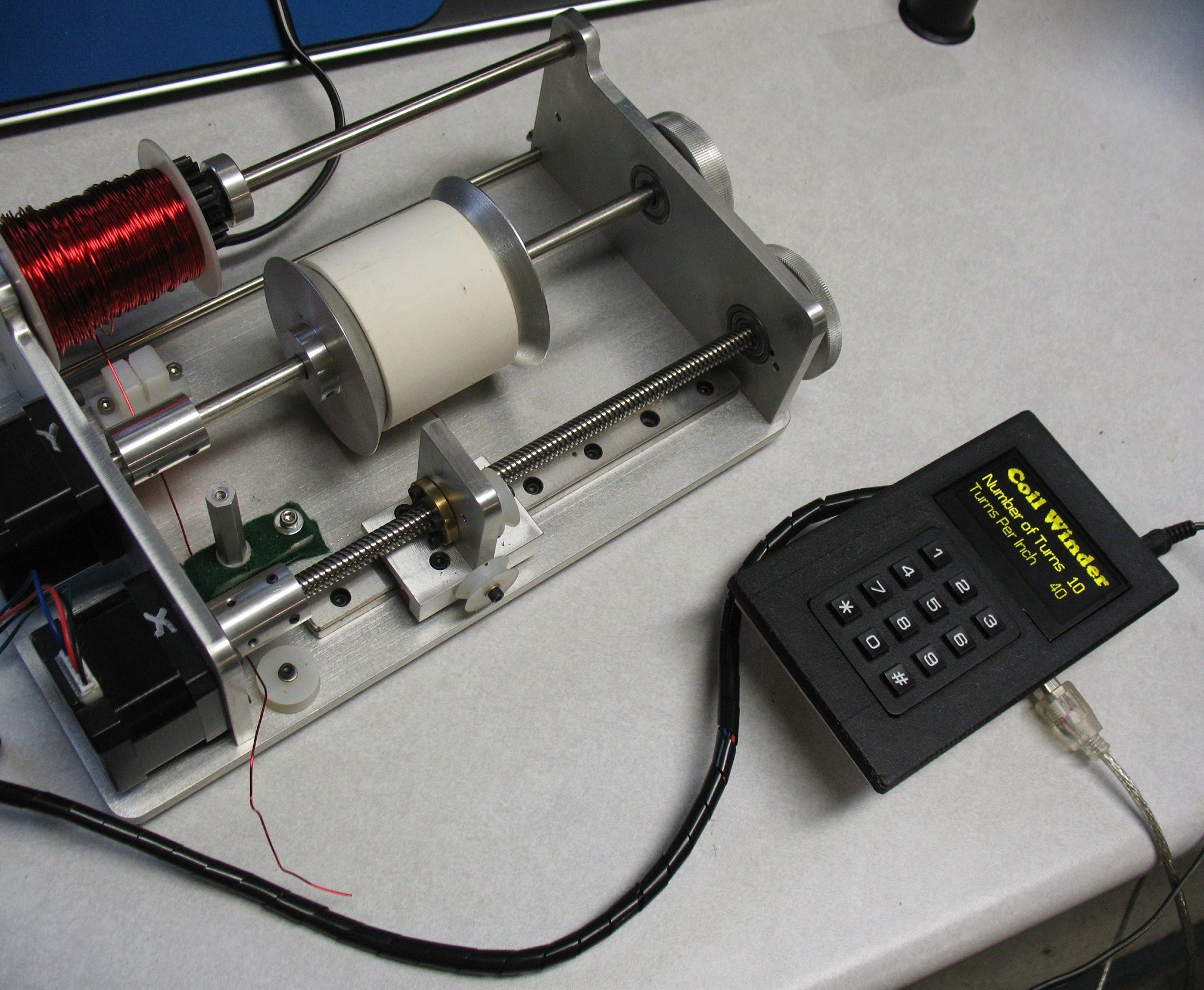

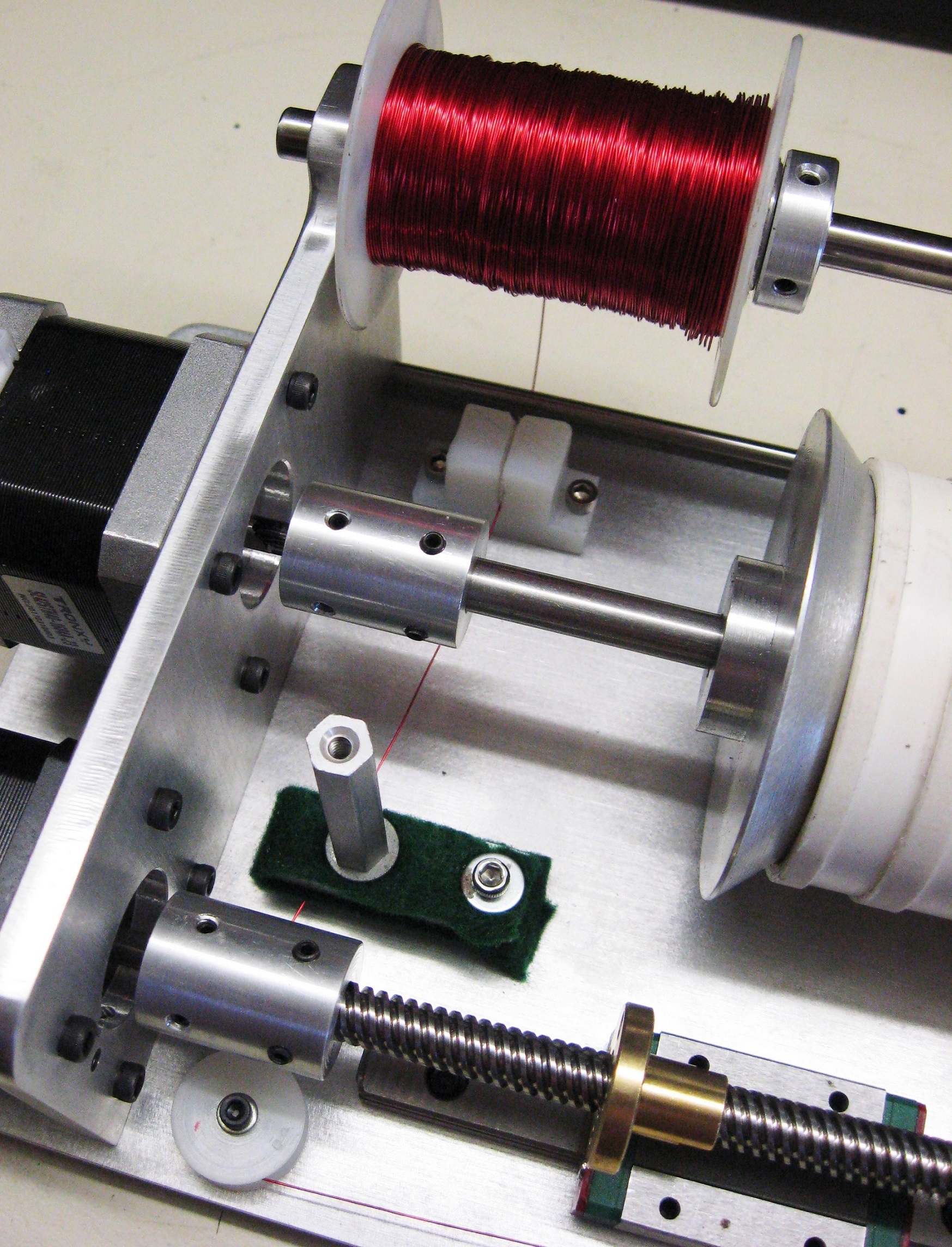

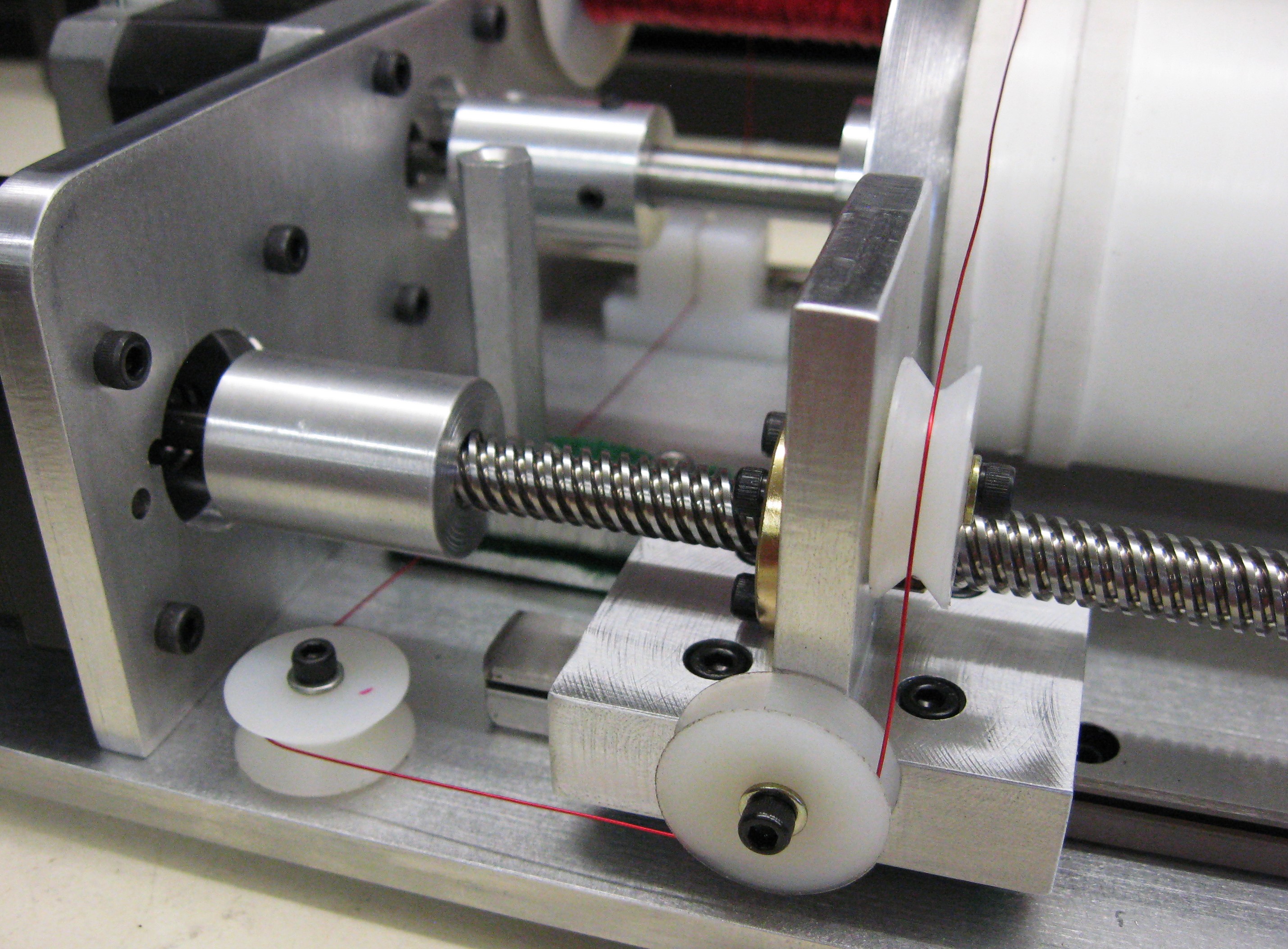

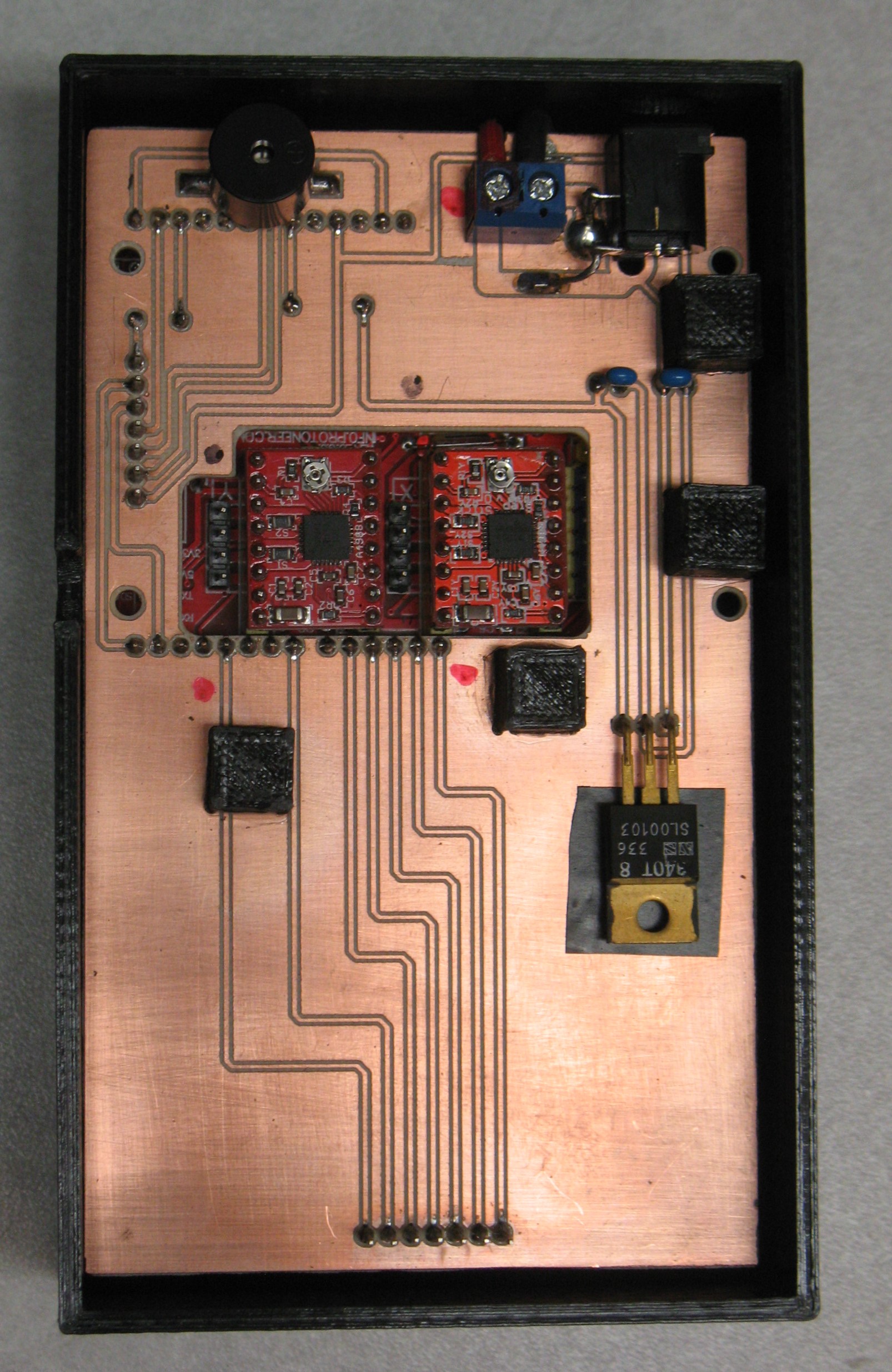

Coil winder made from scratch. Two Nema 17 stepper motors. One glide and one rail. 8 mm lead screw. Arduino Uno. Stepper Motor Shield and two motor controllers. Key Pad and Display. Home made PC Shield. 3D printed box.

3D Printed Box is not perfect but it works.

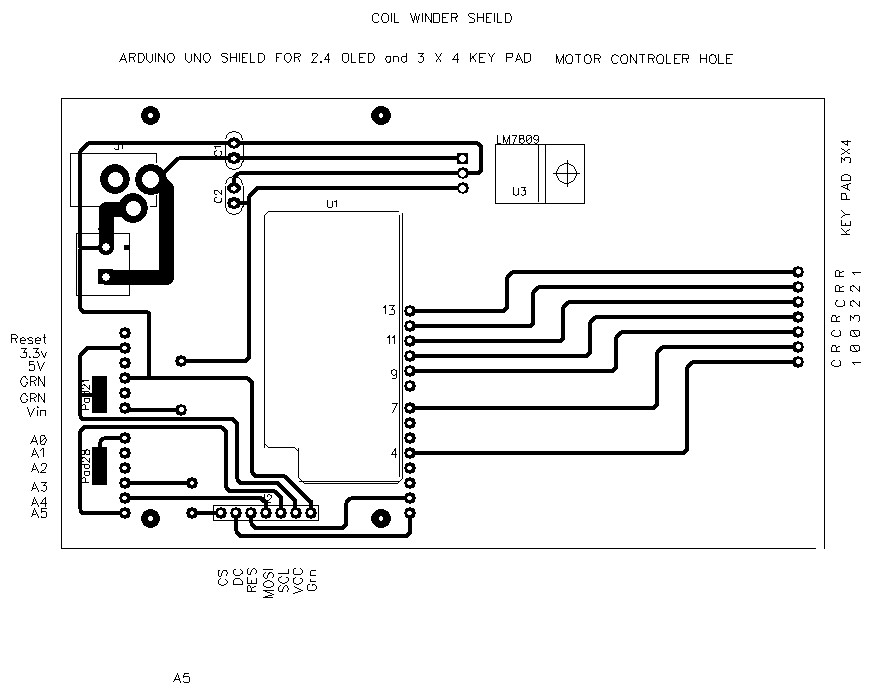

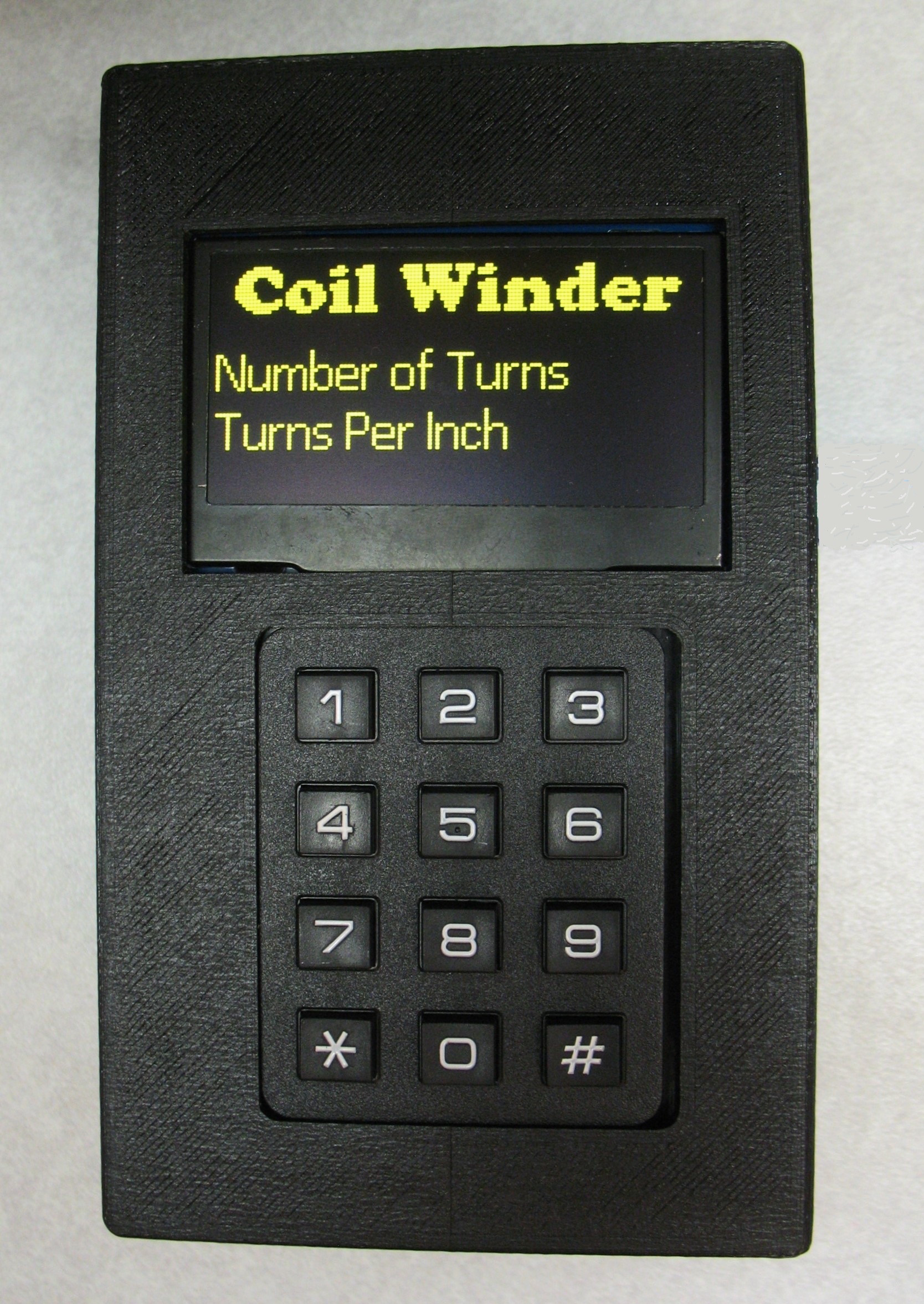

Key Pad and Display Plugged into Header Pins

This Shield plugs into Motor Controller Shield. The Black cubes are printed support blocks. Regulator supplies Voltage from motor power supply to Arduino.

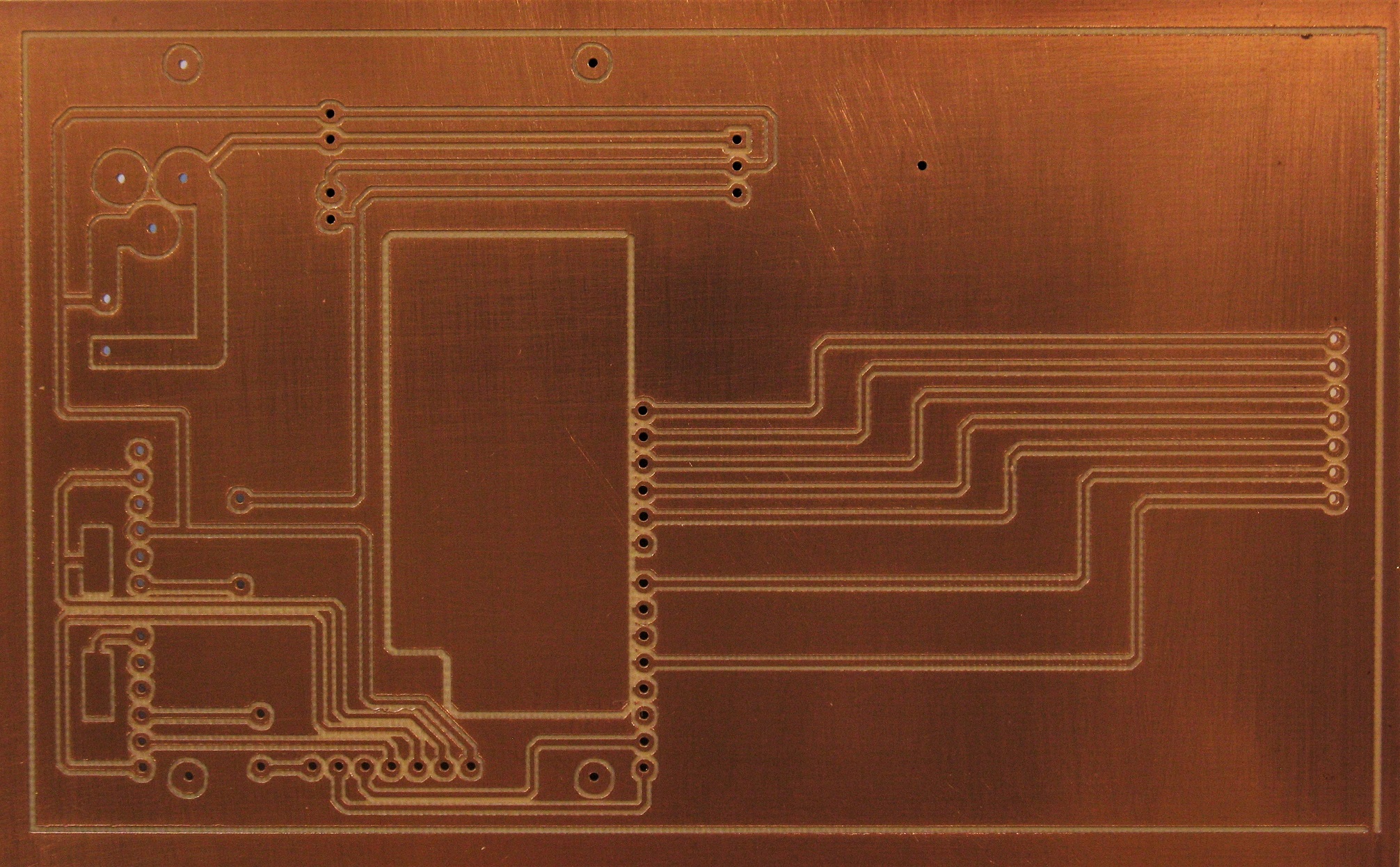

This PC board was made with my home maid PC Router. See it on this web site.

Just tell the controller How many turns you want and at what TPI and you have a coil!

The magic is in the code.

//Winder Shield OLED 2.4 Keypad 3x4 WA6OTP 1/12/2019 3:00 PM

#include <SPI.h>

#include "SSD1306Ascii.h"

#include "SSD1306AsciiSoftSpi.h"

#include <Keypad.h>

// pin definitions

#define CS_PIN A3

#define RST_PIN 1

#define DC_PIN 0

#define MOSI_PIN A4

#define CLK_PIN A5

SSD1306AsciiSoftSpi oled;

const byte ROWS = 4;

const byte COLS = 3;

char keys [ROWS] [COLS] = {

{'1', '2', '3'},

{'4', '5', '6'},

{'7', '8', '9'},

{'.', '0', '#'}

};

byte rowPins[ROWS] = { 7,13,12,10}; //Connect Rows to these Arduino pins

byte colPins[COLS] = { 9,4,11};

Keypad kpd = Keypad( makeKeymap(keys), rowPins, colPins, ROWS, COLS ); // Init Keypad

int outPin2 = 2; // digital pin 2 Step X

int outPin3 = 3; // digital pin 3 Step Y

int outPin5 = 5; // digital pin X Direction

int outPin6 = 6; // digital pin Y Direction

int nwt=0; // Number of wire turns

int pulses=0; // pulse start value

int tpi = 0; // Turns Per Inch

int revs=0; // unknown ?

float (tpidelay); // delay for timing

float (tt); // one turn time lead screw

float (pitch); // wire pitch

float (cl); // coil length

float (trns); // lead screw turns X axis

float (coiltime); // coil time

float(myentry); // Floating point variable for keyboard entry

void setup()

{

oled.begin(&Adafruit128x64, CS_PIN, DC_PIN, CLK_PIN, MOSI_PIN, RST_PIN); //SPI

oled.setFont(Cooper19);

oled.clear();

oled.setCursor(0,0);

oled.println(" Coil Winder");

oled.setFont(Callibri15);

oled.println("Number of Turns");

oled.setCursor(0,52);

oled.print("Turns Per Inch");

pinMode(outPin2, OUTPUT); // sets the digital pin 2 as output X

pinMode(outPin3, OUTPUT); // sets the digital pin 3 as output Y

pinMode(outPin5, OUTPUT); // sets the digital pin 5 as output X

pinMode(outPin6, OUTPUT); // sets the digital pin 6 as output Y

pinMode(8, OUTPUT); // enable motor on coltroller

digitalWrite(2, 0); //set pin 2 low X

digitalWrite(3, 0); //set pin 3 low Y

digitalWrite(5, 0); //set pin 5 High X direction

digitalWrite(6, 0); //set pin 6 High Y direction

digitalWrite(8, 0); //set pin 8 low Enable

}

void loop(){

ReadKeys();

{

nwt=myentry;

oled.setCursor(105,3);

oled.print(nwt);

}

ReadKeys();

{

tpi=myentry;

oled.setCursor(105,5);

oled.print(tpi);

coiltime=(nwt*1.63195); // 1 second / 489.950htz * 800 = time of 1 turns * number of turns, 490.21

pitch = (1.00/tpi); // pitch turn width

cl = (nwt * pitch); // coil length

trns = (cl /.318); // number of lead screw turns, #.318 = movement of caraige

revs=(trns*800); // one turn time of lead screw

tt=(coiltime/trns);

tpidelay=(tt/.80); // delay for timing * .8 insted of 800 toget decimal tocome out right

}

StartMotors(); // Start Motors

}

void StartMotors(){

analogWrite(3, 2); // Y motor 0n ,The duty cycle of "2" gives 16us pulse on 489.950 Hz

for (pulses = 0; pulses < revs; pulses ++) // X count pulse per revolution

{

digitalWrite(outPin2, 1); // X motor sets 2 pin HIGH

delayMicroseconds(10); // X pauses for 10 microseconds

digitalWrite(outPin2, 0); // X motor sets 2 pin LOW

delay(tpidelay); // X pauses for wire gauge

}

analogWrite(3, 0); // Y turn off (low) PWM Y motor

}

#include <SPI.h>

#include "SSD1306Ascii.h"

#include "SSD1306AsciiSoftSpi.h"

#include <Keypad.h>

// pin definitions

#define CS_PIN A3

#define RST_PIN 1

#define DC_PIN 0

#define MOSI_PIN A4

#define CLK_PIN A5

SSD1306AsciiSoftSpi oled;

const byte ROWS = 4;

const byte COLS = 3;

char keys [ROWS] [COLS] = {

{'1', '2', '3'},

{'4', '5', '6'},

{'7', '8', '9'},

{'.', '0', '#'}

};

byte rowPins[ROWS] = { 7,13,12,10}; //Connect Rows to these Arduino pins

byte colPins[COLS] = { 9,4,11};

Keypad kpd = Keypad( makeKeymap(keys), rowPins, colPins, ROWS, COLS ); // Init Keypad

int outPin2 = 2; // digital pin 2 Step X

int outPin3 = 3; // digital pin 3 Step Y

int outPin5 = 5; // digital pin X Direction

int outPin6 = 6; // digital pin Y Direction

int nwt=0; // Number of wire turns

int pulses=0; // pulse start value

int tpi = 0; // Turns Per Inch

int revs=0; // unknown ?

float (tpidelay); // delay for timing

float (tt); // one turn time lead screw

float (pitch); // wire pitch

float (cl); // coil length

float (trns); // lead screw turns X axis

float (coiltime); // coil time

float(myentry); // Floating point variable for keyboard entry

void setup()

{

oled.begin(&Adafruit128x64, CS_PIN, DC_PIN, CLK_PIN, MOSI_PIN, RST_PIN); //SPI

oled.setFont(Cooper19);

oled.clear();

oled.setCursor(0,0);

oled.println(" Coil Winder");

oled.setFont(Callibri15);

oled.println("Number of Turns");

oled.setCursor(0,52);

oled.print("Turns Per Inch");

pinMode(outPin2, OUTPUT); // sets the digital pin 2 as output X

pinMode(outPin3, OUTPUT); // sets the digital pin 3 as output Y

pinMode(outPin5, OUTPUT); // sets the digital pin 5 as output X

pinMode(outPin6, OUTPUT); // sets the digital pin 6 as output Y

pinMode(8, OUTPUT); // enable motor on coltroller

digitalWrite(2, 0); //set pin 2 low X

digitalWrite(3, 0); //set pin 3 low Y

digitalWrite(5, 0); //set pin 5 High X direction

digitalWrite(6, 0); //set pin 6 High Y direction

digitalWrite(8, 0); //set pin 8 low Enable

}

void loop(){

ReadKeys();

{

nwt=myentry;

oled.setCursor(105,3);

oled.print(nwt);

}

ReadKeys();

{

tpi=myentry;

oled.setCursor(105,5);

oled.print(tpi);

coiltime=(nwt*1.63195); // 1 second / 489.950htz * 800 = time of 1 turns * number of turns, 490.21

pitch = (1.00/tpi); // pitch turn width

cl = (nwt * pitch); // coil length

trns = (cl /.318); // number of lead screw turns, #.318 = movement of caraige

revs=(trns*800); // one turn time of lead screw

tt=(coiltime/trns);

tpidelay=(tt/.80); // delay for timing * .8 insted of 800 toget decimal tocome out right

}

StartMotors(); // Start Motors

}

void StartMotors(){

analogWrite(3, 2); // Y motor 0n ,The duty cycle of "2" gives 16us pulse on 489.950 Hz

for (pulses = 0; pulses < revs; pulses ++) // X count pulse per revolution

{

digitalWrite(outPin2, 1); // X motor sets 2 pin HIGH

delayMicroseconds(10); // X pauses for 10 microseconds

digitalWrite(outPin2, 0); // X motor sets 2 pin LOW

delay(tpidelay); // X pauses for wire gauge

}

analogWrite(3, 0); // Y turn off (low) PWM Y motor

}